CYLINDER Block

Introduction:

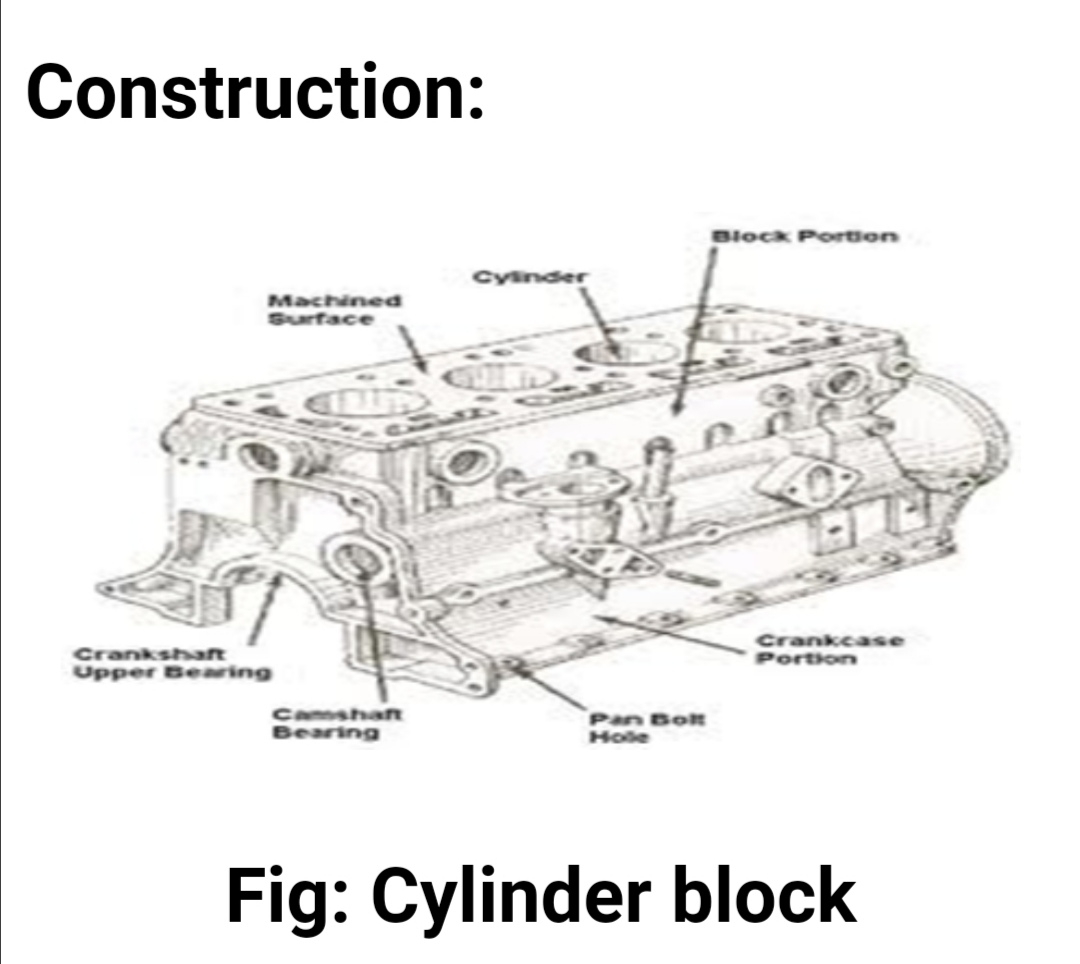

Cylinder block is made by casting and is used to support the cylinder in position. The main structural member of all automotive engines is a cylinder block that usually extends upward from the center line of the main support for the crankshaft to the junction with the cylinder head.

Cylinder block:

- The block serves as the structural framework of the engine and carries the mounting pad by which the engine is supported in the chassis.

- The cylinder block of an automobile engine is a casting with appropriate machined surfaces and threaded holes for attaching the cylinder head, main bearings, oil pan, and other units.

- The crankcase is formed by the portion of the cylinder block below the cylinder bores and the stamped or cast metal oil pan that forms the lower enclosure of the engine and also serves as a lubricating oil reservoir, or sump.

- The cylinders are openings of circular cross section that extend through the upper portion of the block, with interior walls bored and polished to form smooth, accurate bearing surfaces.

Fig: Cylinder block

- There are two arrangements of cylinders in common automotive use—the vertical, or in-line, type and the V type.

- The in-line engine has a single row of cylinders extending vertically upward from the crankcase and aligned with the crankshaft main bearings. The V type has two rows of cylinders, usually forming an angle of 60° or 90° between the two banks. V-8 engines (eight cylinders) are usually of the 90° type. Some small six-cylinder aviation engines have horizontally opposed cylinders.

- A passage bored lengthwise in the block houses the camshaft that operates the valves.

- The location of camshafts for most automotive applications is overhead—overhead cam (OHC) or dual overhead cam (DOHC). A gear, chain, or belt compartment for the camshaft drive from the crankshaft is formed between the front or rear end of the block and a cover plate.

- On virtually all modern engines, a toothed belt is used to ensure accurate and responsive control of the valve train.

- The bell housing is formed at the rear of the cylinder block to enclose the flywheel and provide for attachment of transmission housing. Water jackets are formed around the cylinders with suitable cored connecting passages for circulation of the coolant.

- The cylinder block of the L-head engine is extended to one side of the cylinder bores, with the valve seats and passages for inlet and exhaust, together with the valve guides, formed in this extension of the block.

- The cylinder head of the valve-in-head engine is narrower and deeper and carries the valve seats, valve guides, and valve ports.

Comments

Post a Comment